Overview

Loading dock levelers are a component of a facility that create a bridge from the floor to a truck for loading and unloading to occur. They are especially useful for high traffic docks.

Dock levelers have been around since at least the 1950s, and while the components have evolved since then, their basic design still accomplishes the same task.

Design

Dock levelers have 3 main power styles: pull chain, air powered, and hydraulic. Prices, designs, and components vary with all 3 styles. The main sizes available for levelers include 6', 6.5', and 7' wide by 6', 8', and 10' lengths. These are all nominal sizes, as the actual frame size is lesser than these dimensions. Capacities range most often from 20,000# to 55,000# in 5,000# increments. Note with capacities that these are also nominal. Real world capacities are less than this comparative industry rating. Consult your manufacture for real world capacities.

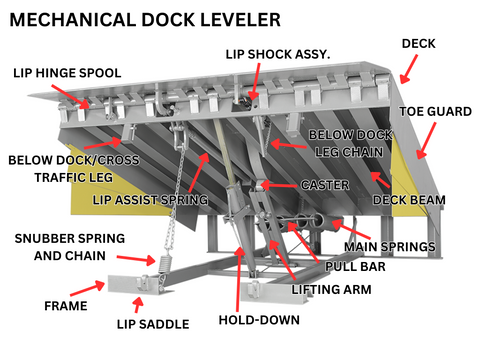

Mechanical Dock Leveler

- Most cost-effective style of leveler

- No electrical requirements

- Great for standard capacity projects

- Future conversions are available

Common Components

- Hold-Down assembly

- Lip activation assembly

- Lip shock

- Main extension spring(s)

- Pull bar

- Lifting Arm

- Snubber chain + spring

- Below dock/cross traffic legs

- Toe guards

- Maintenance strut

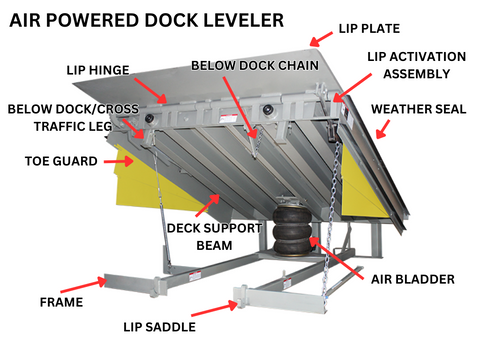

Air Powered Dock Leveler

- Middle ground between mechanical and hydraulic

- Powered, with no hydraulic requirements

- Interlock capable with optional safety features

- Low pressure air for activation

Common Components

- Air bladder

- Below dock/traffic legs

- Air fan, hose and filter

- Lip activation assembly

- Toe guards

- Maintenance strut

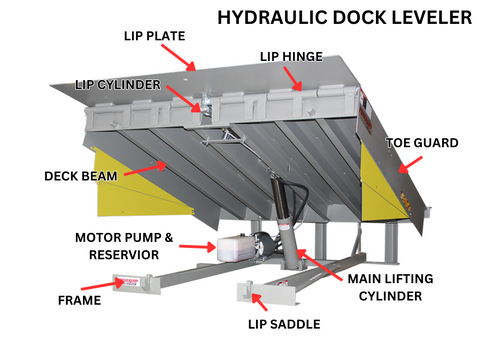

Hydraulic Dock Leveler

- Safest style of leveler

- Minimal components as a more simple design

- Simple push-button operation

- Service range float for easy high/low truck access

- Typically require less maintenance and replacement components

Common Components

- Lip and lifting hydraulic cylinders

- Powerpack (Motor + Pump + Reservoir)

- Logic Block

- Toe guards

- Maintenance strut