A vertical reciprocating conveyor (or VRC for short) is a piece of equipment that most commonly performs movement of materials from one level of a plant or mezzanine to another. They are an important part of maximizing space to improve efficiency and product movement at your business. They are more commonly referred to as freight lifts or a material lift elevator.

As a supplier of freight lifts (in Cleveland OH), we often perform service and repairs for our customers. This includes regular inspections of equipment to ensure operational excellence and safety for employees. Performing service on freight lifts is important to ownership of this asset for performing safely and to last for its intended lifespan. When performing maintenance, you should have an understanding of what to look out for. In this short-form article, we’ll provide a basis of understanding for your lift and help you to maximize its’ lifespan for your business.

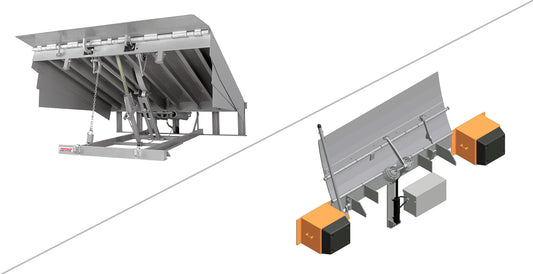

Freight Lift Maintenance

The first item to be sure of is clearing all debris from under and around the lift. Debris is a surprisingly commonly overlooked cause of malfunction with equipment. You should also check the integrity of the surrounding concrete floor and any embedded steel around the lift for any issues that may arise. The next step is to check the frame and to torque all anchors. At this time, all welds should be inspected for cracking or failure.An important part of the operation of the lift are any drive chains or cables. Check for proper operation of all such devices. The under carriage must be inspected for any dishing or deflection and the like. After checking the installation and integrity of the framing, check safety features such as gate interlocking as well as operation. This coincides with all electrical connections which must be checked for proper contact. All failing wire harnesses should be replaced, including any conduit or sealtite. Also common for replacement are lift push buttons, which should be visible and operate as-intended. Next, the motor or pump must be properly operating and all connections should be tight. All switches should be checked for operation, including the pressure switch and interlocks if present.

After the motor, inspect the oil level and add top off if necessary. Refer to manufacture guidelines for oil grade and recommendations. Check hydraulic cylinders for leaks or cracks and hose connections for rotting and leaks. At this time, you can also inspect and tighten all cylinder mounts. Verify the counterbalance and panic valve including the relief valve setting. Check cylinder rod nuts for proper torque settings. Now, you can lubricate all pivot points and components. The final step is to check operation post adjustment and inspection. It is also recommended to verify with any local ordinances for certification or sign off if required.

For a downloadable freight lift preventive maintenance checklist, click here.